Description

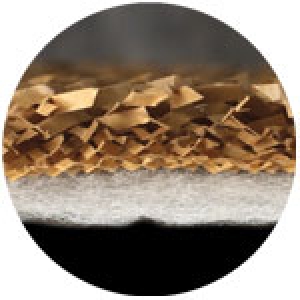

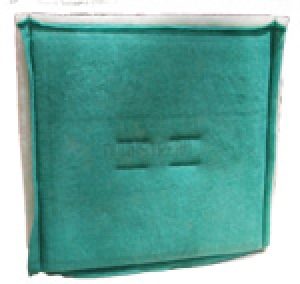

Designed for both batch and conveyorized production systems, Col-Met’s Open Front Bench Booth offers a safe and clean environment for any type of finishing operation. A structural variation of our Open Front Booth design, Col-Met’s Open Front Bench Booths are also suitable for both batch type and automated production systems. Airflow is drawn in through the open front, across the painter and parts being coated, and then exhausted through a filter bank in the back of the booth. Our Open Front and Open Front Bench Booths are engineered for versatility, high efficiency and added convenience. Conveyor pass-through openings can be as much as 25% of the booth open front area, without requiring additional exhaust fan capacity. Specially engineered enclosures may be designed to meet your requirements. — Booth Features •Heavy Duty Construction Booths are constructed from 18-gauge, prime quality galvanized steel and are engineered with corresponding support structure as booth dimensions demand. All panels and support members are precision punched for easy nut and bolt assembly. •Exhaust Chamber A tubeaxial exhaust fan designed specifically for use in paint spray booths powers the airflow through the booth and exhaust stack. All exhaust fans are of non-sparking construction, and motor drive and bearings are sealed from the air stream of the exhaust. Motors are provided with each unit. •Industry-Leading Lighting Lighted booths get bright, full booth illumination from four-tube, 48″ long, 32-watt, fluorescent light fixtures. Col-Met light fixtures are ETL listed (Class 1 Division 2) and are supplied with dual ballasts to accept either 120V or 277V power. Bulbs are included. •Efficient Fans & Motors Quality brand-name tubeaxial fans and motors •Air Solenoid Valve Interlocked to the exhaust fan and air supply for the spray application equipment •Meets Quality Performance Standards Spray booths manufactured by Col-Met meet and/or exceed all applicable OSHA and NFPA regulations. — Booth Options •Air replacement units and intake chambers can be added •Reduced air flows for automatic spray operations •Durable powder coated white option available •Conveyor and crane slots/openings available •Control panel and other electrical components can be purchased separately